What is an Electrostatic Spray Gun?

In the realm of industrial equipment, the tools used can significantly impact the quality, efficiency, and cost-effectiveness of production processes. One such tool that has revolutionized the coating and painting industry is the electrostatic spray gun.

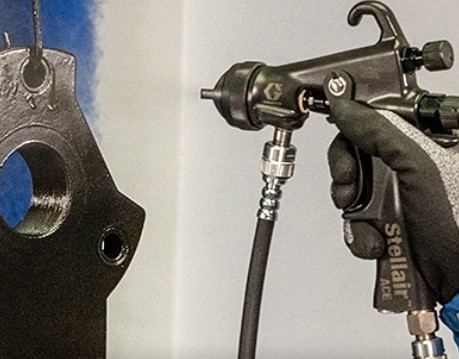

The electrostatic spray gun is used in many industries, such as car manufacturing and furniture production. It offers a high-quality finish. It also provides great accuracy. But exactly what is an electrostatic spray gun, how does it work, and why should industries consider incorporating it into their operations?

Understanding the Technology Behind Electrostatic Spray Guns

At the core of the electrostatic spray gun lies the principle of electrostatics, which deals with the behavior of electric charges that are at rest. The functionality of an electrostatic spray gun is based on this principle, which enables it to efficiently apply coatings to surfaces with minimal waste and maximum coverage.

When the paint or coating material is sprayed from an electrostatic spray gun, it passes through an electrostatic field generated by the gun. This field imparts an electric charge to each particle of the coating material. Typically, the particles are given a negative charge, although positive charges can also be used depending on the application.

The object or surface being coated is usually grounded, which means it has a neutral or opposite charge. Charged particles stick better and more evenly to a grounded surface than they do with regular spray methods.

This attraction results in a “wrap-around” effect, where the coating particles are drawn to the entire surface, including the edges and hard-to-reach areas. This effect not only ensures a more even and consistent coat but also reduces overspray—a common issue in traditional spraying methods where a significant portion of the paint misses the target surface.

The Benefits of Using an Electrostatic Spray Gun

The electrostatic spray gun is lauded for several advantages that make it a preferred choice in various industrial applications. These benefits contribute to improved efficiency, reduced waste, and a higher quality finish, all of which are critical in manufacturing and production settings.

Enhanced Coverage and Uniformity

One of the primary benefits of using an electrostatic spray gun is its ability to provide superior coverage. The electrostatic attraction between the charged paint particles and the grounded surface ensures that the coating is applied evenly across the entire surface, including edges, corners, and recesses. This results in a smooth, consistent finish that is difficult to achieve with conventional spraying techniques.

Moreover, the wrap-around effect means that even complex shapes and contours are coated evenly, reducing the need for touch-ups or additional coats. This not only improves the aesthetic quality of the finish but also enhances the durability and protective properties of the coating.

Increased Material Efficiency

Traditional spray methods often waste a lot of paint, as much of it does not stick to the intended surface. This not only leads to material waste but also requires more frequent refills and increases the overall cost of the coating process.

In contrast, the electrostatic spray gun is highly efficient in its use of materials. The charged particles are strongly attracted to the grounded surface, minimizing overspray and ensuring that more of the coating material ends up on the intended object. This results in less waste, lower material costs, and a more sustainable coating process.

Cost-Effectiveness

The improved efficiency and reduced material waste offered by an electrostatic spray gun translate into significant cost savings for industrial operations. Companies can save money by using less paint or coating material to get the finish they want. Additionally, the reduced need for touch-ups and rework further cuts down on labor costs and production time.

Over time, the investment in an electrostatic spray gun can pay for itself through these cost savings, making it a wise choice for industries that rely on high-quality coatings.

Environmental Benefits

In today’s industrial landscape, sustainability is a key concern. Companies are increasingly looking for ways to reduce their environmental impact while maintaining or improving their production capabilities. The electrostatic spray gun contributes to these efforts by minimizing overspray and reducing the amount of volatile organic compounds (VOCs) released into the environment.

VOCs are harmful chemicals commonly found in paints and coatings that can contribute to air pollution and pose health risks to workers. By using an electrostatic spray gun, industries can lower the amount of paint needed and, consequently, the amount of VOCs emitted. Additionally, many electrostatic spray systems are compatible with low-VOC coatings, further enhancing their environmental benefits.

Improved Safety

Safety is always a top priority in industrial settings, and the electrostatic spray gun offers several features that enhance workplace safety. Traditional spray methods can generate static electricity, leading to the risk of sparks and, in some cases, fires or explosions, particularly in environments where flammable materials are present.

Electrostatic spray guns are designed to mitigate these risks. Controlling particle charging and grounding the surface stops static electricity from building up, lowering the risk of dangerous situations. Additionally, the precision of the electrostatic spray gun allows for more controlled and directed spraying, minimizing the risk of accidental overspray or exposure to harmful chemicals.

Applications of Electrostatic Spray Guns

The versatility of the electrostatic spray gun makes it suitable for a wide range of applications across various industries. While it is most commonly associated with the automotive industry, where it is used to apply paint to vehicles, its use extends far beyond this sector.

In the aerospace industry, electrostatic spray guns are used to apply protective coatings to aircraft components, ensuring durability and resistance to harsh environmental conditions. The furniture industry also benefits from electrostatic spray guns, which are used to apply finishes to wooden and metal furniture, achieving a smooth and durable surface.

In the industrial manufacturing sector, electrostatic spray guns are used to apply coatings to machinery, tools, and equipment, providing corrosion resistance and extending the lifespan of these assets. Additionally, the food and beverage industry uses electrostatic spraying to apply coatings to packaging materials, ensuring product safety and extending shelf life.

Factors to Consider When Choosing an Electrostatic Spray Gun

When selecting an electrostatic spray gun, it’s essential to consider the specific needs of your application. The type of coating material, the surface being coated, and the required finish quality should all influence your choice. Factors such as the size and shape of the objects being coated, the speed of production, and the desired level of automation are also important considerations.

While this article does not focus on specific models or brands, BF Sales offers a wide range of electrostatic spray guns to meet the needs of any industrial application. Their expert team can help you select the right tool for your specific requirements, ensuring that you achieve the best possible results in your coating processes.

The electrostatic spray gun is a powerful tool that has transformed the way coatings are applied in various industries. By leveraging the principles of electrostatics, this innovative device offers superior coverage, increased efficiency, and significant cost savings. Whether you are in the automotive, aerospace, or industrial manufacturing sector, an electrostatic spray gun can help you achieve a high-quality finish while reducing waste and environmental impact.

For more information on the best electrostatic spray gun for your needs, explore the selection available at BF Sales, the premier supplier of industrial equipment. Their knowledgeable staff can guide you in choosing the right equipment to enhance your production capabilities and ensure your success in the competitive industrial landscape.